Nibbler tool for sheet metal cutting has been one of the essential tools for modding and hacking, it has been the tool of choice for cutting out brackets and heat sinks for hot ends from materials sourced from metal enclosures collected from old computer DVD drives.

Nibbler tool for sheet metal cutting has been one of the essential tools for modding and hacking, it has been the tool of choice for cutting out brackets and heat sinks for hot ends from materials sourced from metal enclosures collected from old computer DVD drives.

The hand nibbler tool has provided an opportunity to recycle old household electrical enclosures in to something new when added to 3d printer printed designs. The sheet metal nibbler has worked very well for me, operation is easy, quiet and clean and importantly, convenient and accurate.

Nibbler Tool Features Review

The nibbler tool I have is the Draper Expert Hand Nibbler sheet metal cutter 35748, and I got this from Ebay for less than eleven pounds delivered. It can cut sheet metal up to 1.2mm thickness and laminates and plastics up to 2mm, but I’ve only used these for metal sheets so far, and I’ve been able to cut metal sheets down a scribed line with good accuracy. However, the nibbler tool is not great for cutting out round holes but curvy shapes are possible if they are not too tight. Usually, I can rough cut curves before rounding them off neatly with a Dremel or file.

|

|

It is claimed that a wide variety of materials can be cut cleanly without distortion, a claim I can confirm as being accurate, at least in the case of the salvaged DVD drive enclosures I’ve been using. Other features are the interchangeable cutters and spring loaded handle with slip guards that allow you to comfortably push the hand nibbler forward while cutting sheet metal, and it’s quiet and clean operation will make it ideal for late night hacking.

Nibbler Tool Prerequisite and Usage

When working with sheet metal, other tools and safety gear may be required besides the nibbler tool to complete a project, and a steel rule and scriber would be ideal to have at hand for best mark out ability. Pliers are also good to have for straightening and at least two pliers would be needed for bending and folding the work piece.

While the nibbler tool doesn’t normally make sharp edges from cuts, as a precaution, it’s best to have gloves to put on which would make handling sheet metal a lot more comfortable. Eye protection kit should always be at hand making it a good policy is to wear them as a routine when using tools or when filing and sanding.

I always try to get the best lighting conditions possible when marking out and cutting and sometimes prefer to go outside of the house for best results. Sometimes scribed lines can be difficult to see in shadows so good lighting is essential for cutting accurately. Also when marking out, allow at least 3mm for the cutter to take out as waste from cuts and for the best cutting accuracy, I like to use the hand nibbler tool upside down to make it easier to see the scribed lines.

Putting a little light oil on the moving parts including the cutter will keep the nibbler tool functioning smoothly and make easier work at cutting sheet metal.

|

|

Nibbler tool used in Projects

I originally bought the nibbler tool to put some vent holes in the side of my computer case for extra cooling and now, since owning a 3d printer, it is being put to further use in much more interesting ways, I may even need to buy some spare cutters.

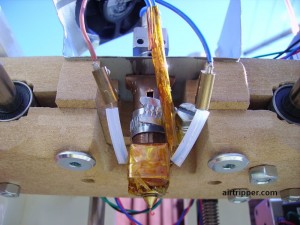

My SUMPOD 3d printer extruder and hot end have gone through a lot of modifications in order to get better performance, and the nibbler tool has been one of the tools essential for making those modifications, such as cutting out hot end brackets, bowden cable brackets, nozzle cold end heat sinks and peek insulator heat sinks.

The materials used for making these brackets and heat sinks have come from old PC DVD drive enclosures and copper pipe, and without the nibbler tool, it would have been difficult to make the cuts and form the shapes needed.

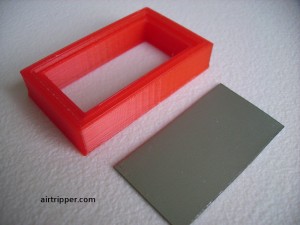

With the nibbler tool there is no need to make everything entirely out of 3d printed plastic, things such as enclosures can be made to look much more interesting by sticking metal panels to plastic frames, hot glue works very well for this.

Sheet metal is all around us waiting to be recycled in to our next project, so before you throw out that old set top box or VCR, skin it first and turn the old enclosures in to something new with the help of the nibbler tool.

[bodyadsrich1l]